สแตนเลสเบอร์ 1และสแตนเลส 2Bเป็นวัสดุสเตนเลสสตีลที่นิยมใช้กันทั่วไปสองชนิด ด้วยคุณสมบัติการกัดกร่อนและความแข็งแรงที่ยอดเยี่ยม จึงนิยมใช้กันอย่างแพร่หลายในหลากหลายสาขา อย่างไรก็ตาม ในสถานการณ์ที่แตกต่างกัน เราจำเป็นต้องเลือกผลิตภัณฑ์ที่แตกต่างกัน บทความนี้เน้นการวิเคราะห์เชิงลึกเกี่ยวกับความแตกต่างระหว่างสเตนเลสสตีลเบอร์ 1 และ 2B เพื่อให้คำแนะนำที่ดียิ่งขึ้นสำหรับลูกค้าที่ใช้วัสดุนี้ในสภาพแวดล้อมที่มีภาระสูง

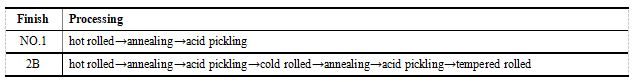

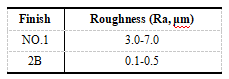

การประมวลผลและความหยาบที่แตกต่างกัน

พื้นผิวหมายเลข 1:หลังจากการรีดร้อน การอบอ่อน การดอง และกระบวนการอื่นๆ พื้นผิวจะเป็นสีขาวเงิน มีพื้นผิวรีดที่เห็นได้ชัด และมีความหยาบค่อนข้างสูง พื้นผิวหยาบตามธรรมชาตินี้มีค่าสัมประสิทธิ์แรงเสียดทานที่ดีกว่า ทำให้มีโอกาสลื่นไถลน้อยลงภายใต้สภาวะที่มีภาระหนัก และเหมาะสำหรับการใช้งานที่ต้องการการยึดเกาะหรือแรงเสียดทาน

พื้นผิว 2B:จากพื้นผิวหมายเลข 1 หลังจากการรีดเย็น การอบอ่อน การดอง และการรีดขึ้นรูป พื้นผิวจะเรียบเนียนขึ้นเรื่อยๆ โดยมีความหยาบน้อยลง แสดงผลด้าน แม้ว่ารูปลักษณ์จะสวยงามกว่า แต่พื้นผิวที่เรียบอาจทำให้เกิดแรงเสียดทานไม่เพียงพอในสภาพแวดล้อมที่มีภาระสูง ซึ่งส่งผลต่อประสิทธิภาพการทำงาน

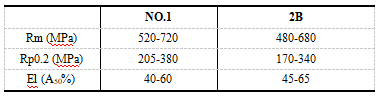

สมบัติเชิงกล

พื้นผิวหมายเลข 1:ด้วยเทคโนโลยีการแปรรูป พื้นผิวหมายเลข 1 จึงสามารถคงไว้ซึ่งแรงกดจากการรีดบางส่วน และมีความแข็งแรงเชิงกลสูงกว่าพื้นผิวหมายเลข 2B เล็กน้อย ความแข็งแรงที่สูงขึ้นนี้ช่วยให้ทนต่อแรงกดและแรงกระแทกได้ดีกว่า และเหมาะสำหรับการใช้งานที่มีภาระสูงและความเข้มสูง

พื้นผิว 2B:หลังจากการอบคืนตัวและการรีด โครงสร้างภายในของพื้นผิว 2B มีความสม่ำเสมอมากขึ้น แม้ว่าจะมีความแข็งแรงต่ำกว่า NO.1 เล็กน้อย แต่คุณสมบัติเชิงกลโดยรวมของ 2B ดีกว่าและมีความเหนียวดีกว่า อย่างไรก็ตาม ในสภาพแวดล้อมที่มีภาระสูง ความแข็งแรงที่ต่ำกว่าอาจเป็นปัจจัยจำกัด

การเปรียบเทียบการใช้งาน

พื้นผิวหมายเลข 1:ด้วยความแข็งแรงเชิงกลที่ยอดเยี่ยมและพื้นผิวที่ขรุขระ พื้นผิว NO.1 จึงเหมาะอย่างยิ่งสำหรับสภาพแวดล้อมที่รุนแรง

- 1. การสร้างชิ้นส่วนโครงสร้าง: ทนทานต่อการกัดเซาะจากลมและฝน รวมถึงแรงโน้มถ่วง พื้นผิวหมายเลข 1 ให้การรองรับและความทนทานที่แข็งแกร่งยิ่งขึ้น

- 2. โครงอุปกรณ์อุตสาหกรรม: ทนทานต่อการสั่นสะเทือนและแรงกระแทกทางกล พื้นผิวหมายเลข 1 ช่วยให้การทำงานของอุปกรณ์มีเสถียรภาพ

- 3.ชิ้นส่วนเครื่องจักรหนัก: ทนทานต่อภาระและการสึกหรอสูง พื้นผิวหมายเลข 1 ช่วยยืดอายุการใช้งานของส่วนประกอบ

พื้นผิว 2B:เหมาะสำหรับการใช้งานที่ต้องการพื้นผิวที่เรียบเนียนและทนต่อการกัดกร่อนสูง

- 1.อุปกรณ์แปรรูปอาหาร

- 2.อุปกรณ์ทางการแพทย์

- 3.อุปกรณ์เคมี

- 4.การตกแต่ง

บทสรุป

พื้นผิวของ NO.1 และ 2B นั้นมีข้อดีของตัวเอง แต่ภายใต้สภาพแวดล้อมที่มีภาระงานสูง พื้นผิวของ NO.1 จะแสดงประสิทธิภาพที่ดีกว่าด้วยความแข็งแรงเชิงกลและความหยาบที่สูงกว่า ทำให้เป็นตัวเลือกที่ดีที่สุดในสภาพแวดล้อมที่รุนแรง

เวลาโพสต์: 21 มี.ค. 2568