347 stainless steel is a high-temperature stable and corrosion-resistant steel, known for its excellent corrosion resistance and good mechanical properties. It is used in manufacturing equipment and components in chemical, petroleum, medical, and food industries. This article will introduce the elemental content, application areas, and advantages of 347 stainless steel

347 Stainless Steel Composition

347 stainless steel is a stabilized austenitic stainless steel based on 18/8 stainless steel (18% Cr, 8% Ni). Its main chemical composition is as follows:

Carbon (C): ≤0.08%

Chromium (Cr): 17.0%-19.0%

Nickel (Ni): 9.0%-13.0%

Iron (Fe): Balance

Molybdenum (Mo): ≤3%

Manganese (Mn): ≤2%

Silicon (Si): ≤1%

Phosphorus (P): ≤0.045%

Sulfur (S): ≤0.03%

Titanium (Ti): 5 * (C+N) ≤1.0%

Niobium (Nb): 10 * (C+N) ≤1.0%

The characteristic of 347 stainless steel is the addition of stabilizer niobium, which gives it good intergranular corrosion resistance. The appropriate content of titanium and niobium effectively reduces the possibility of intergranular corrosion.

347 Stainless Steel Application Areas

347 stainless steel, due to its superior properties, is widely used in the following areas:

1.Petrochemical Equipment: 347 stainless steel, with good high-temperature oxidation resistance and corrosion resistance, is suitable for high-temperature, high-pressure, and corrosive environments, such as cracking units, refining devices, etc.

2.Power Engineering: In high-pressure steam environments like nuclear power stations and thermal power plants, 347 stainless steel can be used as material for heat exchangers, boilers, and other critical components.

3.Food Processing Equipment: Due to its corrosion resistance and high-temperature resistance, 347 stainless steel is applied in food processing equipment, such as cookers, drying equipment, etc.

4.Aerospace: 347 stainless steel has stable performance under high temperature and pressure, suitable for critical components in the aerospace field, like engine parts, gas turbines, etc.

5.Chemical Equipment: 347 stainless steel can be used to manufacture various chemical equipment, such as reactors, storage tanks, etc., especially performing excellently in high-temperature, high-pressure, and corrosive environments.

6.Environmental Equipment: 347 stainless steel is used in various environmental equipment, like waste gas treatment devices, solid waste processing units, etc., having good corrosion resistance and high-temperature performance.

347 Stainless Steel Advantages Analysis

347 stainless steel has the following significant advantages among many stainless steels:

Good Intergranular Corrosion Resistance: Due to the addition of stabilizer niobium, 347 stainless steel has excellent intergranular corrosion resistance during welding, preventing intergranular corrosion in the heat-affected zone and improving the corrosion resistance of the weld joint.

High-Temperature Performance: 347 stainless steel maintains stable mechanical properties and oxidation resistance at high temperatures, suitable for long-term use below 800℃, applicable for critical components in high-temperature equipment.

Stress Corrosion Resistance: 347 stainless steel has good stress corrosion resistance in environments containing chlorides, suitable for corrosive environments like seawater, salt solutions, etc.

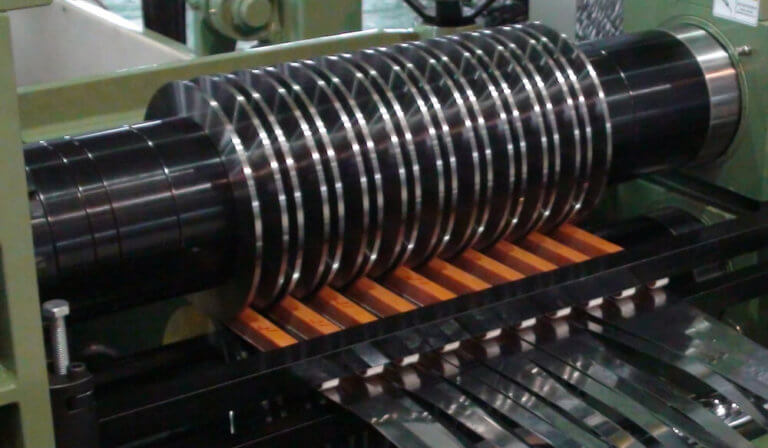

Good Processability: 347 stainless steel has good cold working properties, can be processed and formed by cold rolling, cold drawing, etc., suitable for manufacturing various stainless steel products.

Superior Overall Performance: 347 stainless steel exhibits superior performance in corrosion resistance, high-temperature resistance, stress corrosion resistance, and processability, suitable for various complex environments and high-demand applications.

Conclusion

347 stainless steel, with its excellent corrosion resistance, high-temperature stability, and mechanical properties, is very suitable for use in chemical, petroleum, medical, food, and other fields. Especially in harsh working environments like high temperature, high pressure, and corrosion, the stability and durability of 347 stainless steel are widely recognized and applied.

As technology advances and the pursuit of material properties continues, 347 stainless steel will continue to play its unique advantages in various fields in the future, contributing to the industrial development and quality of life of humanity.

At Aoxing Mill, we specialize in the production of 347 stainless steel, offering a material that excels in high-temperature and corrosive environments. Our commitment to quality ensures that our steel meets the diverse needs of industries ranging from petrochemical to aerospace

Post time: Dec-04-2023