Against the backdrop of the accelerated transformation of the global automobile industry to lightweight, environmentally friendly and high performance, stainless steel has become an indispensable key material in automobile manufacturing with its excellent corrosion resistance, high strength and processing flexibility. As an important market for the global production and application of stainless steel, China has formed a series of mature and widely used steel types, covering the entire industrial chain needs from traditional fuel vehicles to new energy vehicles. This article will introduce the core application of stainless steel and the technical advantages of common steel types in detail from five major fields: exhaust system, body structure, fuel tank, automobile decoration and new energy vehicle batteries.

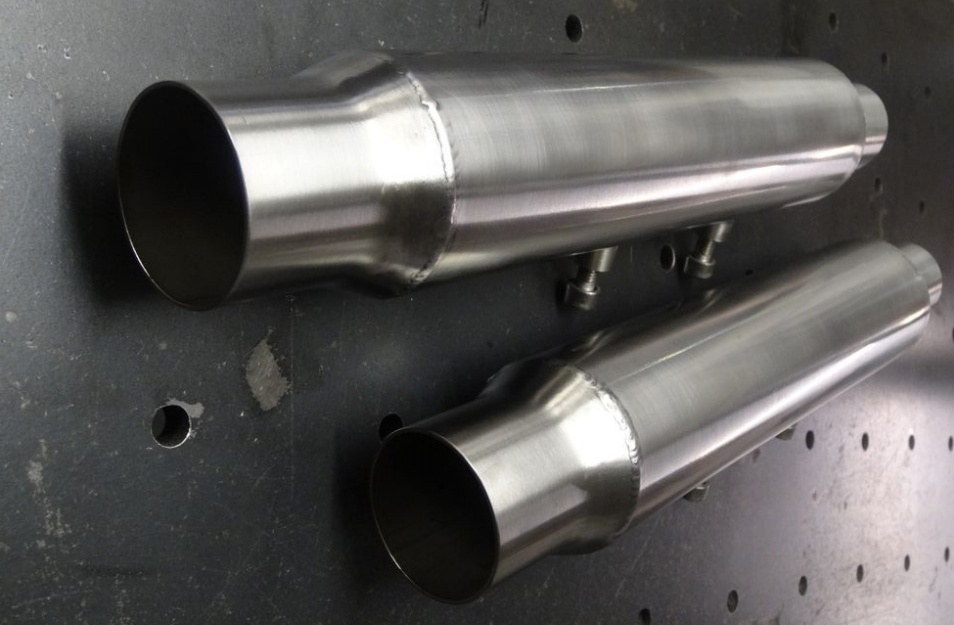

Exhaust System: The “Guardian” Of High Temperature And Corrosion Resistance

The exhaust system is one of the most demanding components in a car, having to withstand multiple challenges such as high-temperature exhaust gases, condensation acid corrosion, and mechanical vibrations. Ferritic stainless steel has become the preferred material in this field due to its low cost, low coefficient of thermal expansion and high thermal conductivity:

409L and 436L: Chinese automakers widely use these two types of steel to make silencers, exhaust pipes and other components. 409L has excellent high-temperature oxidation resistance, while 436L has further improved its salt spray corrosion resistance due to the addition of molybdenum elements.

Domestic high-performance steel: In order to cope with the “National VI” emission standards, the 425M ultra-pure ferrite stainless steel developed by China TISCO has been first used in new models of domestic car companies by optimizing the corrosion resistance and welding performance of cold-end materials.

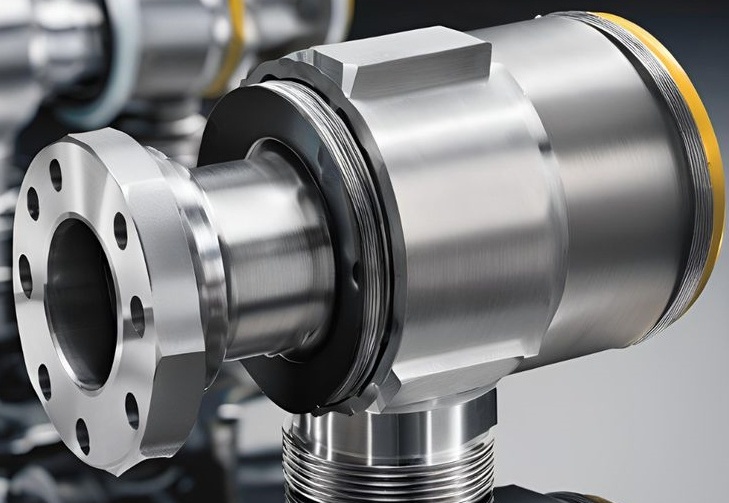

Vehicle Body Structure: A balance Between Lightweight And Safety

304L and 409L: These two steel types are widely used in China’s subway vehicles and large passenger cars. For example, domestic stainless steel subway body reduces weight by 2 tons compared to traditional carbon steel, significantly improving energy efficiency.

Duplex stainless steel: In high-end models, domestic duplex stainless steel (such as 329) is gradually applied to structural parts, such as battery brackets for new energy vehicles due to its high strength and corrosion resistance.

Fuel Tank: A Dual Breakthrough in Safety And Environmental Protection

304L: This steel grades are commonly used by Chinese automakers to manufacture fuel tanks. They have excellent formability and strong corrosion resistance, making them suitable for complex-shaped designs.

Automobile decoration: The Integration Of Aesthetics And Functionality

SUS430 and 304: Widely used in door inserts, wheel hubcaps and other components. SUS430 is low in cost and easy to surface treat (such as bright black and gold), while 304, due to its non-magnetic property and high corrosion resistance, is mostly used in the wipers and antennas of high-end models

New Energy Vehicle Batteries: The Core Guarantee Of Safety

304 cold-rolled precision strip steel: By optimizing the rolling and annealing processes, Taiyuan Iron & Steel (Group) Co., Ltd. has developed battery shell materials with high strength and high surface quality, solving the problem of uneven performance in traditional processes and ensuring the safety and service life of lithium batteries.

High-nickel ternary battery materials: Despite the impact of nickel price fluctuations on costs, domestic high-nickel stainless steel (such as 316L) provides reliable protection for high-energy-density batteries through its corrosion resistance and impact resistance, especially performing exceptionally well in high-humidity coastal environments.

Conclusion

From traditional fuel vehicles to the new energy era, stainless steel, with its multi-functionality and technological innovation, has continuously driven the automotive industry towards high efficiency, safety and environmental protection. Whether it is the high-temperature resistant exhaust system, the lightweight body structure, or the highly safe battery housing, domestic steel grades in China (such as 409L, 304L, and 430) have already possessed the technical strength to compete with international brands.

Post time: Apr-24-2025