2205 duplex stainless steel, consisting of 22% chromium, 3% molybdenum, and 4.5% nickel-nitrogen alloy (austenite-ferrite), stands out for its exceptional properties. Known as 2205 duplex steel, this nitrogen-enhanced stainless steel boasts high strength, excellent impact toughness, and superior resistance to both overall and localized stress corrosion. Its versatility is evident as it is particularly suitable for temperatures ranging from -50°F to +600°F, with potential for use beyond these limits considered for specific alloys.

The 2205 duplex steel is distinguished by its yield strength of 400-550MPa, double that of conventional austenitic stainless steels. This characteristic enables designers to reduce weight in product design, leading to material savings and a cost-effective alternative to 316 and 317L alloys, especially in applications where corrosion resistance is crucial, such as in harsh medium environments like seawater and high chloride content.

Physical and Mechanical Properties of Duplex 2205 Stainless Steel

Density: 8.0g/cm³.

Tensile Strength: ≥620Mpa.

Yield Strength: ≥450Mpa.

Elongation: ≥25%.

Corrosion Resistance of Duplex 2205 Stainless Steel

Uniform Corrosion: The high chromium (22%), molybdenum (3%), and nitrogen (0.18%) content of 2205 steel offers superior corrosion resistance in most environments compared to 316L and 317L.

Localized Corrosion: The composition of chromium, molybdenum, and nitrogen provides strong resistance against pitting and crevice corrosion in oxidizing and acidic solutions.

Stress Corrosion Resistance: The duplex microstructure of 2205 steel enhances its resistance to stress corrosion cracking. Austenitic stainless steels, under specific conditions of temperature, tensile stress, oxygen, and chlorides, are prone to chloride stress corrosion, limiting the use of 304L, 316L, and 317L.

Corrosion Fatigue: The high strength and corrosion resistance of 2205 steel afford it excellent corrosion fatigue strength, making it suitable for processing equipment subject to corrosive environments and cyclic loading.

Structure of Duplex 2205 Stainless Steel

After undergoing a solid solution annealing treatment at 1900°/1922°F (1040°/1080°C), 2205 duplex steel achieves an optimal microstructure of 50% α / 50% γ.

Applications of 2205 Duplex Stainless Steel.

The versatility of 2205 duplex steel spans across various fields: neutral chloride environments, the petrochemical industry, pipelines for the chemical industry, oil and gas sectors, pulp and paper manufacturing, fertilizer production, urea and phosphate industries, seawater applications, energy and environmental industries, light industry and food sector, equipment for the food and pharmaceutical industries, high-strength components, subsea pipelines, flue-gas desulfurization, desalination plants, sulfuric acid plants, marine engineering fasteners, and more.

As a specialized steel, 2205 surpasses conventional stainless steels in both hardness and performance, marking it a superior choice for a wide range of applications.

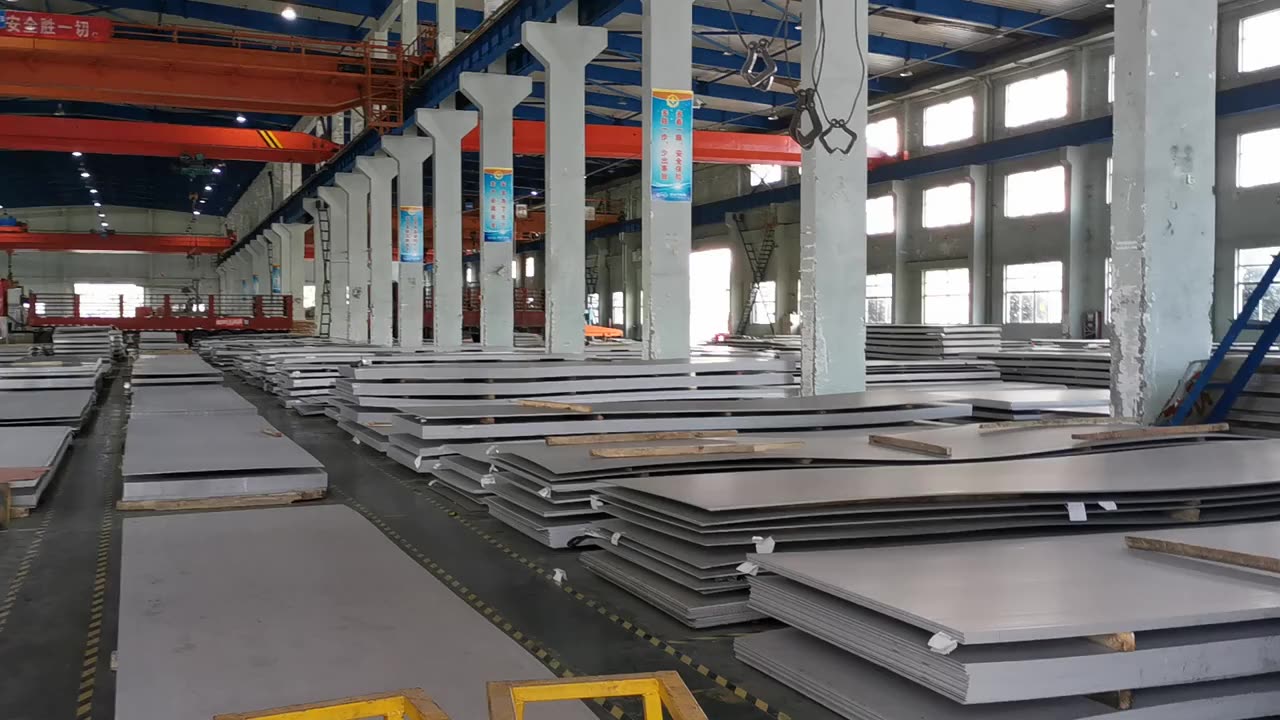

Discover Our Premium 2205 Stainless Steel Coil and Sheet Products

At the heart of countless engineering and design successes, our 2205 stainless steel coil and sheet offerings stand out for their exceptional quality and versatility. Whether you’re crafting robust industrial components or intricate decorative elements, our product range is designed to meet your every need.

We invite you to explore our extensive selection of 2205 stainless steel coil and 2205 stainless steel sheet products. Discover the ideal material for your next project, backed by our commitment to quality and customer satisfaction. Visit our product pages today to learn more about the specifications, applications, and advantages of our premium 2205 stainless steel offerings.

Post time: Apr-07-2024