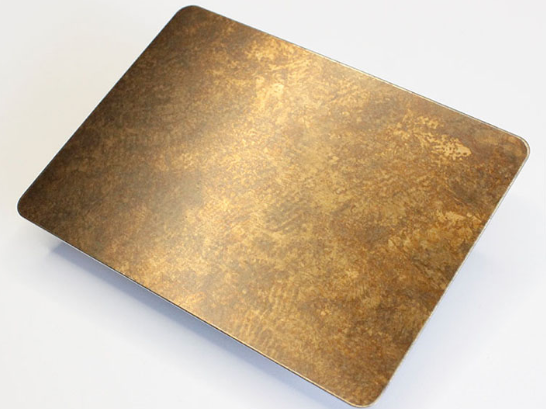

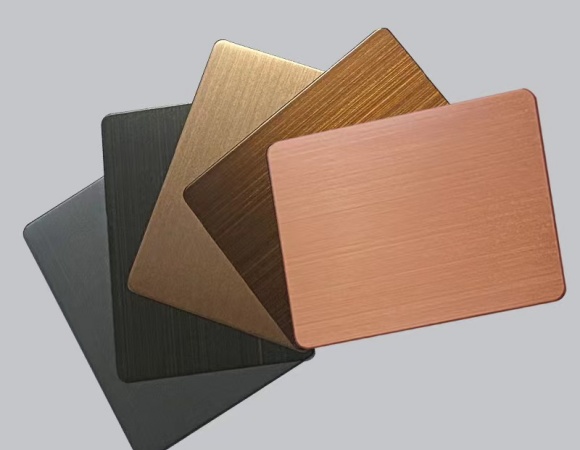

Colored stainless steel sheets have gained immense popularity in various industries, thanks to their aesthetic appeal and durability. However, one crucial factor that significantly influences their performance is thickness. Understanding how the thickness of these decorative stainless steel sheets affects their durability, weight, and suitability for specific projects is essential for making informed decisions.

1.Understand the Application Requirements

Structural Needs: If the stainless steel will be used in load-bearing applications, a thicker sheet (e.g., 1.5 mm) may be necessary for strength and durability.

Aesthetic Considerations: For decorative purposes, thinner sheets (e.g., 0.3mm to 0.8mm) can provide flexibility and a more polished finish.

2.Consider the Environment

Indoor vs. Outdoor: For outdoor applications, thicker sheets provide greater resistance to weather and corrosion.

Exposure to Harsh Conditions: If the sheet will be exposed to high temperatures, chemicals, or frequent wear, a thicker material might be more suitable.

3.Workability and Forming

Thicker sheets are harder to shape and form, while thinner sheets are more flexible.For projects requiring intricate designs or detailed patterns, thinner sheets may be easier to manipulate and install.

4. Cost and Budget

Thicker stainless steel sheets tend to be more expensive. Choose a thickness that balances durability with cost-effectiveness.

In conclusion, the thickness of colored stainless steel sheets is a critical factor that affects their durability, weight, and overall suitability for various projects. By carefully considering these aspects, designers and builders can select the right stainless steel sheet to meet their specific needs, ensuring both aesthetic appeal and long-lasting performance.

Post time: Jan-07-2025