Negli attuali standard di sicurezza alimentare globali sempre più rigorosi, la scelta dei materiali per l'imballaggio alimentare influisce direttamente sulla qualità, la sicurezza e la sostenibilità dei prodotti. Grazie alle sue eccellenti proprietà fisiche e alla sua stabilità chimica, l'acciaio inossidabile è diventato uno dei materiali preferiti nel settore del packaging alimentare. Questo articolo analizzerà le caratteristiche principali dell'acciaio inossidabile, le tipologie di materiali comunemente utilizzati e i loro specifici scenari applicativi nell'industria alimentare, svelandone il valore insostituibile.

Cinque caratteristiche fondamentali dell'acciaio inossidabile

1.Eccellente resistenza alla corrosione

L'elemento cromo presente nell'acciaio inossidabile può formare una pellicola di ossido denso (strato di passivazione) sulla superficie, in grado di resistere efficacemente a mezzi corrosivi quali acqua, liquidi acidi e sale, di evitare la migrazione degli ioni metallici e di contaminare gli alimenti, garantendo la sicurezza a lungo termine.

2. Adattabilità ad ambienti ad alta e bassa temperatura

L'acciaio inossidabile mantiene prestazioni stabili nell'intervallo da -196 °C a 800 °C, adatto alla sterilizzazione ad alta temperatura (come la sterilizzazione delle lattine), alla refrigerazione a bassa temperatura (come i contenitori per il trasporto della catena del freddo) e ad altri scenari difficili, garantendo che non vi siano deformazioni o precipitazioni chimiche durante il processo di confezionamento.

3. Antibatterico naturale e facile da pulire

Superficie liscia e senza pori, in grado di inibire la crescita batterica; soddisfa i rigorosi requisiti di igiene alimentare e riduce il rischio di contaminazione microbica con processi di pulizia standardizzati come i sistemi di pulizia CIP.

4. Elevata resistenza e durata

Il materiale ad alta durezza è resistente agli urti e all'usura, riutilizzabile e dura decenni, riducendo i costi di sostituzione frequente e conformandosi al concetto di sviluppo sostenibile.

5.100% di proprietà ambientali riciclabili

L'acciaio inossidabile può essere riciclato all'infinito e il processo di produzione è a basse emissioni di carbonio e rispettoso dell'ambiente, aiutando le aziende alimentari a raggiungere gli obiettivi di una filiera verde.

Materiali in acciaio inossidabile comunemente utilizzati nel settore del confezionamento alimentare

1.acciaio inossidabile 304(Scelta standard di qualità alimentare)

Composizione: 18% cromo, 8% nichel (acciaio inossidabile 18/8)

Vantaggi: elevata versatilità, resistenza agli acidi deboli e agli alcali deboli, ampiamente utilizzato in contenitori per alimenti, attrezzature di lavorazione, stoviglie e così via.

Certificazione: conforme agli standard FDA, GB 4806.9 e altri standard internazionali per i materiali a contatto con gli alimenti.

2.acciaio inossidabile 316L(aggiornamento ad alta resistenza alla corrosione)

Composizione: Aggiunto elemento di molibdeno al 2% sulla base di 304

Scenario applicativo: ambiente fortemente acido e con sale elevato (ad esempio lavorazione dei frutti di mare, attrezzature per il riempimento di salse), migliora significativamente la resistenza alla corrosione

3.acciaio inossidabile 430(opzione economica)

Composizione: 17% cromo, senza nichel

Caratteristiche: basso costo, adatto per ambienti asciutti o per il contatto a breve termine con componenti alimentari (come le parti decorative dell'imballaggio esterno)

Quattro principali scenari applicativi dell'acciaio inossidabile nell'industria alimentare

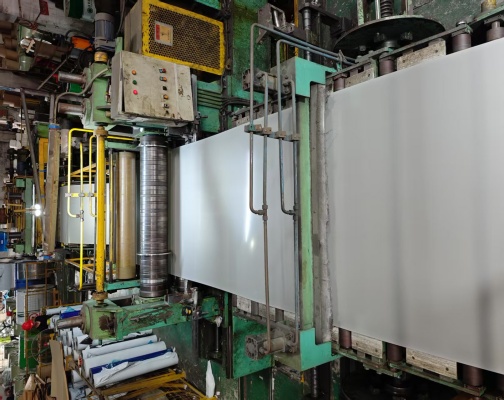

1. Attrezzature per la lavorazione degli alimenti e linee di produzione

Dai serbatoi di miscelazione delle materie prime, ai fermentatori, fino ai tubi di riempimento, le attrezzature in acciaio inossidabile sono impiegate in tutto il processo di produzione di latticini, bevande e condimenti, garantendo un ambiente di produzione privo di inquinamento e facile da mantenere.

2. Contenitori per lo stoccaggio e il trasporto a lungo termine

Il grande serbatoio di stoccaggio e la scatola logistica della catena del freddo sono realizzati in acciaio inossidabile, in grado di resistere al trasporto marittimo a lunga distanza e ai ripetuti carichi e scarichi, per prevenire l'ossidazione e il deterioramento degli alimenti, in particolare per i prodotti ad alto valore aggiunto come vino e olio commestibile.

3.Contenitore per alimenti pronti al consumo

Lunchbox, thermos, stoviglie portatili e altri contenitori per alimenti entrano in contatto diretto con gli imballaggi, grazie alla resistenza antibatterica e al calore dell'acciaio inossidabile, per garantire la sicurezza e la comodità dei consumatori.

4.Soluzioni di imballaggio intelligenti

Gli imballaggi in acciaio inossidabile, abbinati a tag RFID e alla tecnologia di controllo intelligente della temperatura, aiutano le aziende alimentari a ottenere una tracciabilità e un monitoraggio della qualità completi, migliorando al contempo la credibilità del marchio.

Scegli l'acciaio inossidabile per rafforzare la sicurezza alimentare e il valore del marchio

L'acciaio inossidabile non è solo sinonimo di materiali, ma anche un importante mezzo per le aziende alimentari per costruire una linea di difesa di sicurezza e praticare la responsabilità sociale. La sua affidabilità lungo tutto il ciclo di vita, dalla lavorazione delle materie prime al consumo finale, offre al settore una soluzione che bilancia prestazioni e tutela ambientale..

Data di pubblicazione: 13-03-2025